How Lab Grown Diamonds Are Made?

Lab Created Diamonds Vancouver or synthetic diamonds are made within highly controlled environments in laboratories. These lab-grown diamonds are made by highly specialized engineers and scientists using cutting-edge technology. You will find such laboratories across many different parts of the world, such as the USA, Israel, India and China. Using methods such as High Pressure High Temperature (HPHT) and Chemical Vapor Deposition (CVD), Custom Lab Diamond Rings Vancouver are created where they replicate the natural process.

What Are Lab-Grown Diamonds Made Of?

Lab created diamonds have the same chemical composition as natural diamonds, which is carbon! These diamonds are real diamonds and have no physical or chemical attributes which would make them different from mined diamonds. When lab diamonds are created, the scientists or engineers make sure that the carbon atoms form a structure that replicates natural diamonds. Since their physical optics and internal structure are the same, you will only be able to tell the difference through specialized equipment.

Difference Between Lab Grown Diamonds and Natural Diamonds

Lab-grown and natural diamonds do not have any differences, apart from their origin. Lab-grown diamonds may often be confused with diamond simulants, which are not actual diamonds but look similar in appearance. Only a jeweler can tell the difference between lab-grown and natural diamonds if they use a diamond tester. It is specialized equipment to differentiate naturally formed diamonds from diamonds grown in labs. Moreover, unlike diamond mining, diamond labs do not hamper the environment or disrupt communication, making diamond creation more ethically safe.

Different Types of Grown Diamonds

In the laboratory, both processes need to start with a "diamond seed". It is a thin crystal slice that has the thickness of a human hair. Both processes require several weeks to complete. Here's more on the process of how to make lab grown diamonds in two different methods:

Chemical Vapour Deposition (CVD) Process: Key Steps

- Seed Crystal Preparation

- Carbon Plasma Creation

- Diamond Growth

- Cooling and Extraction

In this process, a diamond is created from a hydrocarbon gas mixture. The diamond slice is first placed within a chamber. Then, some gases such as methane and hydrogen gases are heated at high temperatures, which turn into plasma. These are then exposed to the diamond slice. This results in diamond formation within a few weeks. These diamonds are identical to natural diamonds but are created in a lab or grown in a lab.

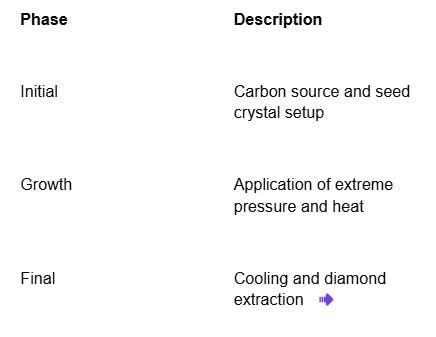

High Pressure High Temperature (HPHT) Process: Key Steps

- Carbon Source Preparation

- Seed Crystal Placement

- High Pressure Application

- High-Temperature Application

- Diamond Growth

- Cooling and Extraction

A small slice of diamond seed is taken and kept in a containment box in this process. The containment box also contains other carbon-mixed gasses such as methane and is tightly sealed. These slices of diamonds typically are then exposed to high temperatures, around 1500°C. and pressure about 1.5 million PSI. The breakdown of the gasses by ionization allows them to merge with the diamond seed, after which diamonds form and grow on top of the small diamond seed. This is how man-made diamonds are formed using the HPHT diamond. This method replicates the high-temperature conditions under the earth's crust, the same way as natural diamonds can be created using natural phenomena.

CVD Diamonds Vs HPHT Diamonds

During the diamond production, CVD diamond requires less resources and time. However, the quicker process results in poorer quality of man made diamonds. CVD diamonds may also contain brown undertones, spotty inclusion and more flaws such as internal graining. If such undesirable features exist within the rough diamond, usually it is given further treatment using the HPHT method. However, if you find quality CVD diamonds, then you won't be able to tell them apart from high-quality HPHT diamonds.

HPHT diamonds are typically of more high-quality because it is formed under similar conditions just like natural diamonds. Natural diamonds are also given HPHT treatment if there are some undesirable qualities present within the diamond crystal. Both CVD and HPHT diamonds have the same properties as natural diamonds and are considered genuine diamonds by the diamond industry.

From blueprint to lab-grown diamond

The Blueprint Phase

The process of creating a lab-grown diamond begins with meticulous planning. Scientists start by designing a blueprint that outlines the desired characteristics of the diamond, including:

- Carat weight

- Color grade

- Clarity

- Cut specifications

This blueprint serves as a guide throughout the entire manufacturing process, ensuring that the final product meets the intended specifications.

Growth Chamber Preparation

Once the blueprint is finalized, technicians prepare the growth chamber. This involves:

- Cleaning and sterilizing the chamber

- Loading the carbon source (typically pure graphite)

- Inserting the diamond seed

- Setting up temperature and pressure controls

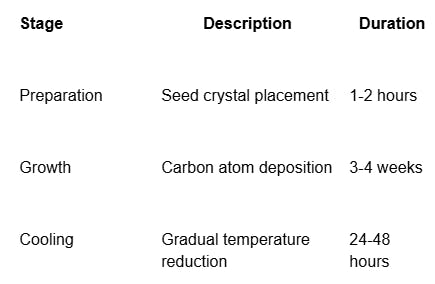

The Growth Process

Depending on the chosen method (CVD or HPHT), the growth process can take several weeks to months. During this time:

- Carbon atoms gradually accumulate on the diamond seed

- The crystal structure forms layer by layer

- Technicians monitor and adjust conditions as needed

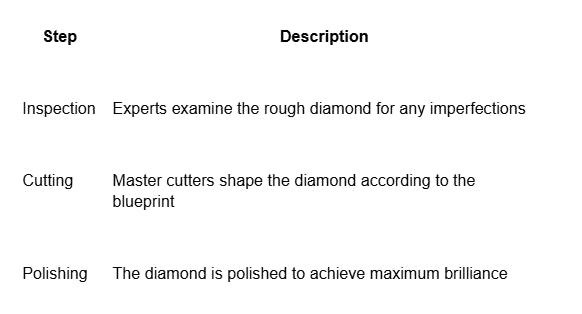

Quality Control and Cutting

After the growth phase, the rough diamond undergoes rigorous quality control:

Finally, the lab-grown diamond is ready for certification and sale, having transformed from a simple blueprint into a dazzling gem.

Final Thoughts

The production of diamonds in labs replicates the natural conditions under which diamonds form. These diamonds are grown under highly controlled environments and have the same physical properties as natural diamonds.

Find Your Perfect Diamond Engagement Ring!

Discover the beauty, ethics, and affordability of lab-grown diamonds. A stunning, sustainable choice for your jewelry. Shop now or learn more!